Soundproofing Tips for Concrete Flooring in Urban New Haven

Concrete Flooring New Haven

Urban living near busy transportation hubs like Union Station and State Street Station creates significant noise challenges that require specialized soundproofing solutions for concrete flooring systems. New Haven residents in downtown areas along Chapel Street and State Street experience elevated noise levels from train traffic, street activity, and neighboring units that can dramatically impact quality of life without proper acoustic treatment.

Understanding Urban Noise Sources

Urban concrete flooring is impacted by a variety of noise transmission pathways, including the airborne sounds created by the traffic and other noises generated by local activities; also, the impact noise (footsteps, dropping objects), which travels through rigid concrete structures as a result of vibrating impacts. Properties located adjacent to railroad lines have the additional issue of low-frequency vibration caused by rail traffic that causes the rebar in the concrete to vibrate, resulting in an increased level of structure-borne noise propagation through the entire building system.

Impact Noise Transmission

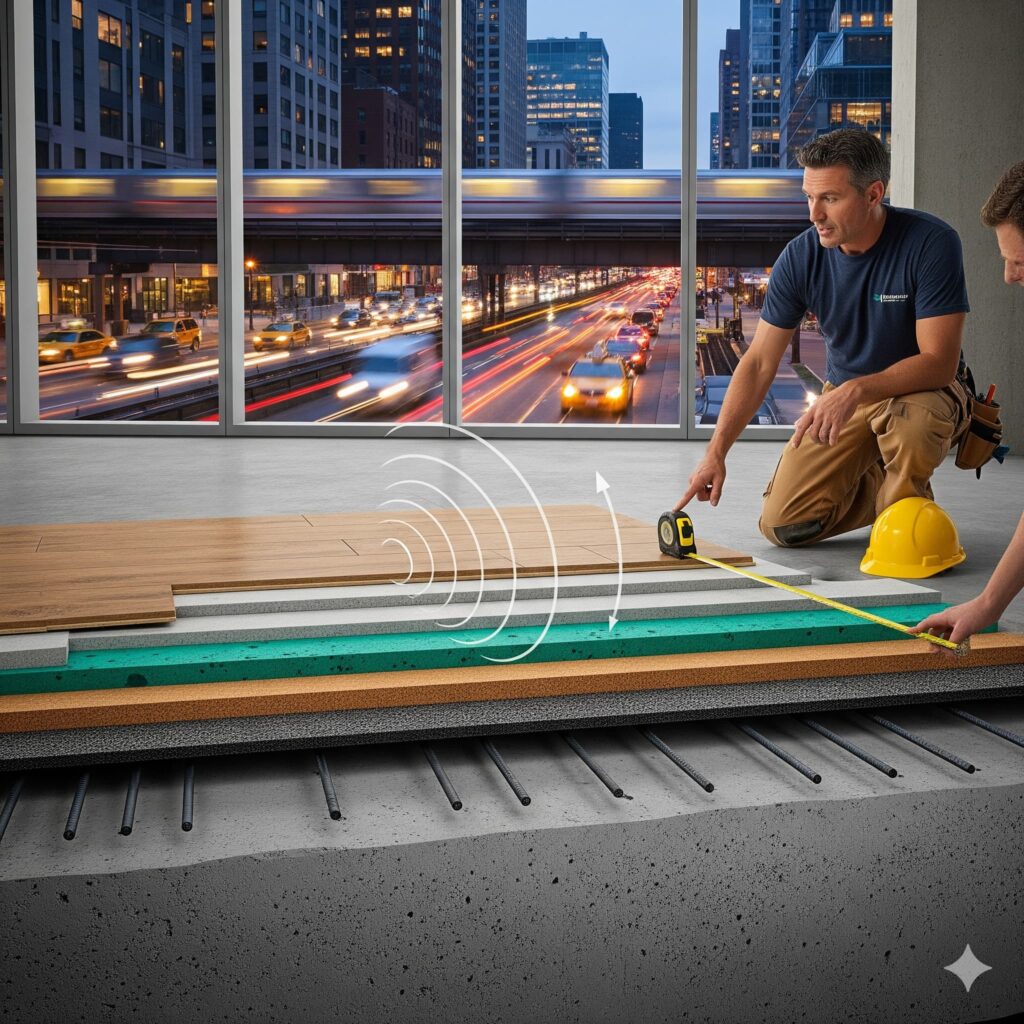

The rigid nature of concrete creates a pathway for all impacts to be transformed into audible impact noise that will travel through structural connections to the adjacent units and floors below. Typical standard concrete slabs generally achieve I.I.C. ratings ranging from 25 to 32. Therefore, it is necessary to develop specialized underlayment systems that will intercept the vibration prior to it entering the structural element to alleviate this deficiency.

Airborne Sound Penetration

Although concrete provides sufficient mass to block airborne noise, there are numerous acoustic weak spots in the performance of concrete due to gaps around the perimeter edges, penetrations for utilities, and structural connections that allow airborne sound to penetrate and compromise overall performance. For example, the constant traffic noise created by Interstate 95 and the Oak Street Connector can create penetration through the above mentioned vulnerabilities; therefore, sealing and isolation of these vulnerabilities is essential to achieving successful control of the airborne sound.

High-Performance Acoustic Underlayments

Acoustic underlayment systems create an essential isolation layer between the concrete sub-flooring and finish floor materials to significantly reduce both impact and airborne noise transmission. Modern rubber and polymer-based systems are available that achieve delta IIC ratings ranging from 22 to 25 decibels and will transform the noisy concrete surface into a quiet living space.

Dense Rubber Underlayment Systems

High-density rubber-based underlayment systems provide superior sound dampening through the use of specialized polymer formulations that absorb impact energy while maintaining the structural integrity of the system under heavy loads. Dense rubber underlayment systems function exceptionally well for properties located near the downtown business district, where both pedestrian and vehicle traffic create continuous noise challenges. Installation of these systems requires precision attention to joint sealing and perimeter isolation to avoid acoustic bridging.

Multi-Layer Isolation Platforms

Advanced floating floor systems utilize multiple layers of acoustic materials, such as mass-loaded vinyl barriers, resilient foam cores, and decoupling membranes to address both impact and airborne noise. These comprehensive solutions perform exceptionally well in environments near transportation infrastructure where multiple noise sources require broad-spectrum acoustic control.

Mass Loaded Vinyl Barriers

Mass-loaded vinyl (MLV) provides superior airborne noise blocking capabilities through the use of dense, flexible membranes that add acoustic mass without increasing the height of the barrier. The specialized materials used in MLV contain high-density mineral fillers that effectively block sound transmission and yet remain thin enough for renovation applications in existing buildings.

Installation Techniques for Maximum Effectiveness

Continuous coverage without gaps or punctures of the MLV is required to ensure maximum performance of the barrier. Seams of the MLV must overlap and seal completely, and avoid any mechanical connections that could create an acoustic bridge to structural elements. Properties near State Street Station would benefit from MLV applications that address both rail noise and urban traffic sounds.

Integration with Existing Floor Systems

MLV barriers can be easily integrated with many types of flooring materials, including hardwood, laminate, tile, and carpet systems, without affecting the installation procedure or finish appearance of the flooring. Additionally, the flexible material will accommodate building movement and thermal expansion while maintaining acoustic performance during its extended service period.

Acoustic Mats and Carpeting

Acoustic carpet systems and specialized mats provide both comfort and sound absorption for concrete flooring applications where hard surface finishes may increase noise problems. These solutions function exceptionally well in residential applications where walking comfort and acoustic performance requirements exist.

High-Density Acoustic Carpet Pads

Professional-grade carpet pads designed for acoustic applications provide significantly improved sound absorption compared to standard residential carpet pad materials. These specialized carpet pads will reduce both impact noise transmission and improve room acoustics by reducing sound reflection and reverberation associated with hard-surfaced urban environments.

Modular Acoustic Mat Systems

Interlocking modular acoustic mat systems provide flexible solutions for areas requiring temporary or adjustable sound control while providing easy access to the concrete surface for maintenance or utilities. These modular acoustic mat systems function exceptionally well for basement workshops, exercise areas, or multi-purpose spaces where acoustic needs may change over time.

Perimeter Isolation and Gap Sealing

Comprehensive acoustic treatment requires careful attention to the perimeter details of the flooring system, where the flooring meets walls, columns, and penetrations through concrete slabs. Small gaps at these locations can significantly compromise acoustic performance by allowing flanking transmission around the carefully designed isolation system.

Sealants for Perimeter Gaps

Specialized acoustic sealants remain flexible and provide excellent sound blocking capabilities for the gaps around the perimeter of the flooring system and utility penetrations. These sealants remain effective through building movement cycles and prevent acoustic short circuits that can undermine costly soundproofing investments.

Expansion Joint Treatment

Acoustic treatment of expansion joints is essential to maintain sound isolation while accommodating structural movement. Installation of acoustic treatment for expansion joints requires professional techniques using resilient materials that compress and expand with concrete movement while maintaining acoustic seal integrity.

Treatment of Door and Transition Areas

Doorways and transitions between different flooring systems are potential acoustic weak points that require specialized treatment to maintain overall soundproofing performance. These areas experience high traffic volumes and must maintain acoustic isolation between spaces.

Acoustic Door Sweeps and Seals

High-performance door sweeps and seals are designed to control noise transmission through the gaps under doors and around frames without compromising door operation or creating maintenance issues. These door sweeps and seals function exceptionally well for controlling hallway noise in multi-unit buildings commonly found in the downtown area of New Haven.

Design of Thresholds for Acoustic Treatment

Transition areas between acoustically treated floors and adjacent spaces require careful design to maintain sound isolation while providing smooth and safe pedestrian traffic flow. Properly designed threshold areas will ensure acoustic continuity across these critical interfaces.

Considerations for Professional Installation

To successfully treat the acoustics of concrete flooring, specialized knowledge of sound transmission principles, material compatibility, and installation techniques that optimize performance while ensuring long term durabilityise required. Professional installation eliminates common errors that can compromise acoustic performance or create future maintenance problems.

Requirements for Surface Preparation

Proper surface preparation ensures optimal bonding and performance of the acoustic materials applied while addressing any pre-existing concrete defects that may affect the quality of the installation. Surface preparation should include crack repair, surface leveling, moisture testing, and contamination removal to create ideal conditions for the installation of the acoustic system.

Verification of Quality and Performance Testing

All professional installations include verification of quality and performance testing to verify that the acoustic system installed performs to design specifications and provides the expected noise reduction benefits. Verification of quality and performance testing identifies potential issues early in the project cycle and documents the performance of the acoustic system for warranty purposes.

Maintenance and Long-Term Performance of Acoustic Flooring Systems

Acoustic flooring systems require very little maintenance if properly installed; however, regular inspections will assist in identifying potential issues prior to them becoming a problem and preserving the acoustic benefits of the system while protecting the value of the investment made in the system.

Inspection Protocols and Preventive Maintenance

Inspection protocols should focus on the perimeter seals, transition areas, and high traffic volume areas where wear may compromise the acoustic performance of the system. Identification of maintenance needs early in the process will eliminate the possibility of minor issues escalating into costly repairs or failure of the acoustic system.

New Haven Concrete Company understands the unique acoustic challenges presented by urban living and can help you evaluate and implement soundproofing solutions that complement your existing concrete flooring. Our staff has experience with the specific noise challenges experienced by downtown New Haven residents and can suggest the best acoustic treatments for your particular application.